Company

Hassmann SA is distinguished by its dynamism, production capacity, quality, inventories, and flexibility to meet the market's needs, always seeking full customer satisfaction.

Our History

Browse by time

Hassmann today

Today, the company occupies a prominent place in the fasteners field, having an installed capacity to produce more than forty thousand different types of screws, rivets, and special parts, always following strict quality standards.

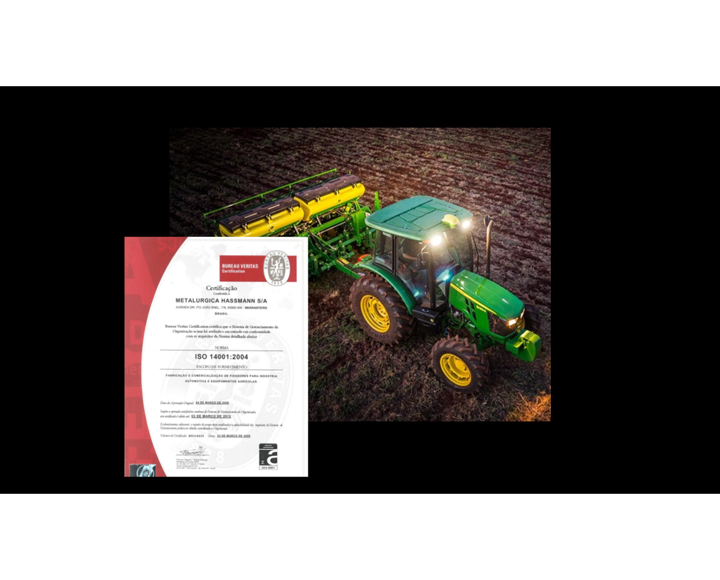

As a result of this capacity, Hassmann has a solid position in the market, supplying its products to the Automotive, Agricultural, Truck, Construction Machinery industries, among others.

With Quality and Environmental Management Systems implemented and certified for decades, Hassmann has consolidated a high-quality standard, as well as a deep respect for the environment and the next generations.

Our certifications

Downloadable documents

Download

Download

Download

Download

Download

Download

Download

Download

factory area + warehouse in the city of Imigrante/RS - Brazil

highly skilled employees

current production capacity, with constant investments to increase production

and export to all continents

Productive capacity

Get to know our solutions

Cold forming

Gauges (min/max)

- Millimeter line: M5 to M24

- Inch line: 1/4" to 1"

Length (min/max)

- Millimeter line: 8mm to 320mm

- Inch line: 3/8" to 12"

Hot forming

Gauges (min/max)

- Millimeter line: M6 to M30

- Inch line: 1/4" to 1.1/8"

Length (min/max)

- Millimeter line: 200mm to 800mm

- Inch line: 8" to 30"

Resistance Classes

ISO 898-1: 4.6/4.8/5.8/6.8/8.8/9.8/10.9/12.9

SAEJ429: Grades 2/5/8

Surface finishes

- Trivalent White Zinc Plating

- Trivalent Yellow Zinc Plating

- Hexavalent Yellow Zinc Plating

- Trivalent Olive Green Zinc Plating

- Trivalent Black Zinc Plating

- Zinc Iron

- Transparent Zinc Nickel

- Black Zinc Nickel

- Hot-Dip Galvanized

- Silver Geomet

- Black Geomet

- Zinc Phosphate

- Manganese phosphate

- Copper

- Tin

- Thermal Black Oxide

Locking elements

- Nylok Patch

- Nytemp

- Precote

- Driloc

- Scotch Grip

- Nycote

- Nytork

- Nystay

- Vibraseal

- Technological 15"

More than 70 years in the business.

Where we are

Imigrante/RS | Brasil

Zip code 95885-000 +55 51 3754 0700 see on google maps

Imigrante/RS | Brasil

Zip code 95885-000 +55 51 3754 0700 see on google maps

Caxias do Sul/RS

Zip code 95044-107 +55 54 3209 1166 see on google maps

Tampa, FL, 33634 | USA +1 786 881 3890 see on google maps